Introduction

Having been involved in the field of Artificial Intelligence (AI) for years, I can attest that becoming proficient in this field is not an easy undertaking. The complexity stems from its multi-dimensionality. In other words, gaining competence in AI requires competencies in math, statistics, computer programming, cloud computing, among others. Despite its complexity, the fundamental concept behind AI is very simple. The basic premise behind Machine Learning (the most common form of Artificial Intelligence) is pure and simple and it simply states that the operational historical data of any system or organization contain precious data nuggets that can be used to predict future outcomes.

Nothing more and nothing less.

The predictive power of Machine Learning models can come handy in many use cases such as finance (determine which applicant gets a loan), medicine (making sense of X-Rays), human speech (smart speakers such as Alexa), and many others. All of these use cases have three things in common. First and foremost, the ability to predict outcome is of great value and can be monetized. Secondly, they have a wealth of digitized historical data needed to train Machine Learning models. Lastly, they have access to computational resources needed for number crunching. We are fortunate that the same concepts are directly applicable to an industrial equipment setting since predictive maintenance is of a great value. The only aspect that might cause a bit of concern is that heavy machinery vendors are slightly behind when it comes to data availability.

Background

A leasing company in the business of leasing heavy machinery used in mining industry is highly motivated to develop a predictive model to help classify various field failures. A typical vehicle relies on many hydraulic pumps used in various aspects of the operation. Malfunctioning pumps are the leading cause of the failures. Hydraulic pumps and other subsystems in the vehicle are monitored by nearly 200 sensors measuring a multitude of parameters such as temperature, vibration, and pressure levels. Operators can have access to sensor readings but typically lack the tools to identify the failure based on sensor reading. Failures come in many varieties but a great majority of them can be dealt with in the field assuming the site carries roughly 20 types of spare parts (mostly switches, relays, and fuses that are relatively inexpensive, small, and easily interchangeable). Based on historical records only 2.5% of the failures are serious enough to justify returning the vehicle to the service center while in absence of predictive tools almost 100% have to be decommissioned.

Objective

The round-trip time for decommissioning and repairing a failed vehicle is roughly 2 weeks and its overall cost exceeds100 times greater than a case where the problem can be dealt with in the field. The objective of this project was to develop a predictive computer model (based on Machine Learning) able to predict whether the repairs can be done in the field or there is a need for decommissioning.

Consider Two Scenarios

For starters let us consider two scenarios. The first scenario begins when an equipment that fails with seemingly an unknown reason. After exhausting a few basic checks; the operator decides to decommission the vehicle and send it back to the regional service center for repairs (after all the asset is a rental). The second scenario too, start with a mysterious failure, but the similarities end there. The pursuit continues by contacting the regional center to verbally convey a handful of sensor readings (ultimately this process can be automated) which are fed into the predictive model. The predictive model is able, with high degree of accuracy; predict the cause of the failure. If local repair is a possibility, the model identifies the module that need replacement.

Outcomes

Our objectives were clear, and the value proposition was apparent. We had marching order to develop a Machine Learning computer model running on a computer located in the regional service center that can be used by individuals with only basic computer skills. The inputs to the model were sensor readings and general field observations, and the outcomes were a likely failure code and a sensible repair plan.

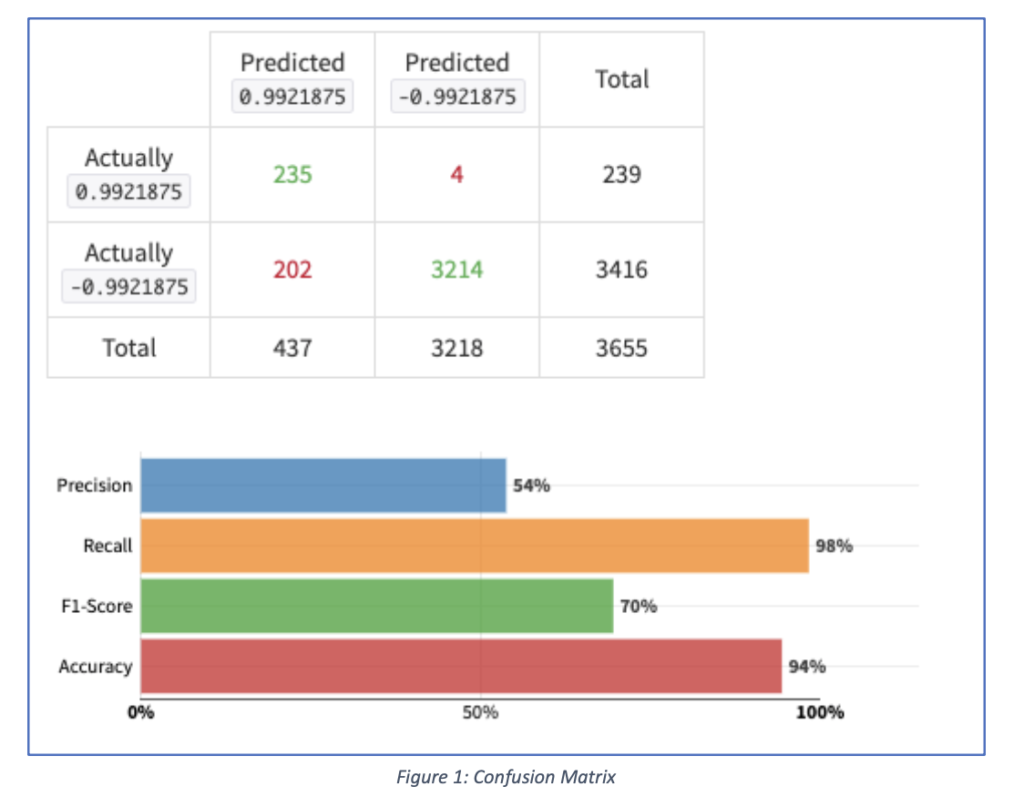

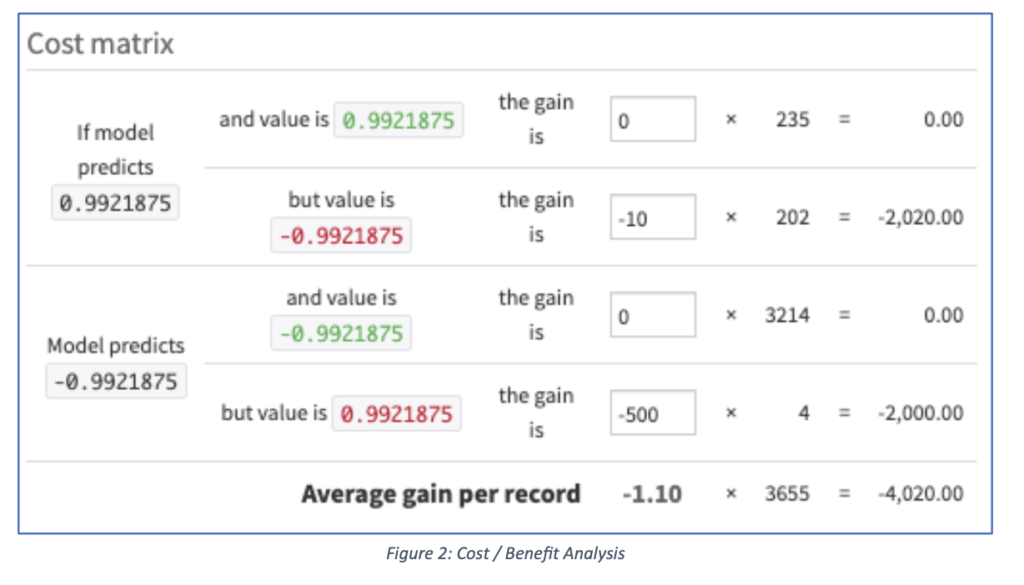

An XGBoost Machine Learning model was developed to take on the challenge of classifying the failures. Fig. 1, Fig. 2, and Fig. 3 contain parameters that can help evaluate the efficacy of the model. While going through all the parameters is outside the scope of this article, I find the following three metrics (in Fig. 1) to be extremely telling:

- Recall (98%): Assuming the failed vehicle does require decommissioning (positive prediction), the predictive model was able to correctly predict this outcome 98% of the times

- Precision (54%): Among all positive cases predicted by the model, 54% of them have been true. At the first blush this metric seems to be mediocre but consider that randomly guessing a correct positive outcome is only 2%

- Accuracy (94%): The model has been able to make right predictions (positive and negative) 94% of the times

Concluding Thoughts

- The historical operational data of your equipment contain golden insights. Don’t let it go to waste

- Treat data as a valuable asset and do all you can to preserve it and make it accessible

- If “predicting outcomes” has value in your business, Machine Learning is definitely the way to go. While blind adoption of AI is suboptimal, building a Machine Learning prototype to test the waters is quick, inexpensive, and extremely telling

Looking back at this project, the process of developing, training, and using a predictive Machine Learning model was the easy part of the project. Most time and effort were spent on collecting and cleaning the training data and transforming it to a format that is understandable by a computer. If forced to summarize the findings of this project in three statements, the following three will be the ones:

Al Gharakhanian is the Managing Director at Cogneefy (cogneefy.com). Cogneefy is a Machine Learning system integration organization specializing in implementation of fully automated Machine Learning pipelines for a variety of use cases. The company has expertise and human resources to tackle all aspects of the project or complement the internal resources of its customers